Difference between revisions of "Template:Page:Featured"

Jump to navigation

Jump to search

m |

m |

||

| Line 1: | Line 1: | ||

[[File:Silo_Cleaning_System_01.jpg|110px|right]] | [[File:Silo_Cleaning_System_01.jpg|110px|right]] | ||

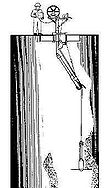

'''Silo cleaning systems''' are specialized systems used to maximize the efficiency of storage silos that hold bulk powders or granules. In silos, material is fed through the top and removed from the bottom. Typical silo applications include animal feed, industrial powders, cement, and pharmaceuticals. | '''Silo cleaning systems''' are specialized systems used to maximize the efficiency of storage [[silos]] that hold bulk powders or granules. In silos, material is fed through the top and removed from the bottom. Typical silo applications include animal feed, industrial powders, cement, and pharmaceuticals. | ||

Free movement of stored materials, on a first-in, first-out basis, is essential in maximizing silo efficiency. The goal of silo efficiency is to ensure that oldest material is used first and does not contaminate newer, fresher material. Two main problems, rat holing and bridging, complicate silo efficiency. When rat holing occurs, powders adhere to the sides of silos. Bridging occurs when material blocks at the silo base. [[Silo Cleaning Systems|Read more..]] | Free movement of stored materials, on a first-in, first-out basis, is essential in maximizing silo efficiency. The goal of silo efficiency is to ensure that oldest material is used first and does not contaminate newer, fresher material. Two main problems, rat holing and bridging, complicate silo efficiency. When rat holing occurs, powders adhere to the sides of silos. Bridging occurs when material blocks at the silo base. [[Silo Cleaning Systems|Read more..]] | ||

Revision as of 08:09, 22 June 2013

Silo cleaning systems are specialized systems used to maximize the efficiency of storage silos that hold bulk powders or granules. In silos, material is fed through the top and removed from the bottom. Typical silo applications include animal feed, industrial powders, cement, and pharmaceuticals.

Free movement of stored materials, on a first-in, first-out basis, is essential in maximizing silo efficiency. The goal of silo efficiency is to ensure that oldest material is used first and does not contaminate newer, fresher material. Two main problems, rat holing and bridging, complicate silo efficiency. When rat holing occurs, powders adhere to the sides of silos. Bridging occurs when material blocks at the silo base. Read more..