Difference between revisions of "Angle Valves"

| Line 7: | Line 7: | ||

* Please start editing this page after the /noinclude | * Please start editing this page after the /noinclude | ||

* -------------------------------------------------></noinclude> | * -------------------------------------------------></noinclude> | ||

[[File:Angle Valves.jpg|thumb|right|Angle Valves]] | |||

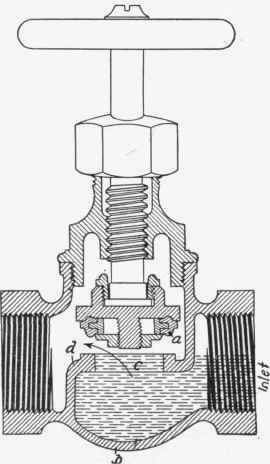

Angle Valve is a manually operated valve with its outlet opening oriented at right angles to its inlet opening; used for regulating the flow of a fluid in a pipe. | [[File:Angle Valves1.jpg|thumb|right|Angle Valves]] | ||

'''Angle Valve''' is a manually operated valve with its outlet opening oriented at right angles to its inlet opening; used for regulating the flow of a fluid in a pipe.It is a valve for controlling the flow of a liquid or air; the fluid leaves at right angles to the direction in which it enters the valve. | |||

Angle Valves are important industrial fittings, deriving their name from the the 90º configuration of inlet and outlet ports. Metallic angle valves in material such as stainless steel, bronze, brass are used for cryogenic applications requiring extreme temperatures, ranging from 450º to -250ºC. High quality of materials used and workmanship ensure longevity and trouble-free service of these valves. | Angle Valves are important industrial fittings, deriving their name from the the 90º configuration of inlet and outlet ports. Metallic angle valves in material such as stainless steel, bronze, brass are used for cryogenic applications requiring extreme temperatures, ranging from 450º to -250ºC. High quality of materials used and workmanship ensure longevity and trouble-free service of these valves. | ||

==Method of operation== | |||

Sometimes referred to as air-operated angle seat valves or externally operated valves, angle valves are operated by a pressurised pilot medium, often air.The valve features a [[Pneumatic Actuators]]. The pilot medium flows into the actuator cylinder under pressure and causes the piston to act so that the seat seal opens or closes permitting or prohibiting flow. | |||

==Angle Valve Applications== | |||

Typical applications include: | |||

* Air drying equipment | |||

* Autoclaves | |||

* Bottling equipment | |||

* Cooling | |||

* Dispensing equipment | |||

* Dye mixing | |||

* Gas | |||

* Ink mixing | |||

* Liquids | |||

* Paint mixing | |||

* Pollution management | |||

* Pre-heating | |||

* Process control | |||

* Steam distribution | |||

* Sterilisers | |||

* Textile equipment | |||

Revision as of 23:50, 29 December 2012

Angle Valve is a manually operated valve with its outlet opening oriented at right angles to its inlet opening; used for regulating the flow of a fluid in a pipe.It is a valve for controlling the flow of a liquid or air; the fluid leaves at right angles to the direction in which it enters the valve.

Angle Valves are important industrial fittings, deriving their name from the the 90º configuration of inlet and outlet ports. Metallic angle valves in material such as stainless steel, bronze, brass are used for cryogenic applications requiring extreme temperatures, ranging from 450º to -250ºC. High quality of materials used and workmanship ensure longevity and trouble-free service of these valves.

Method of operation

Sometimes referred to as air-operated angle seat valves or externally operated valves, angle valves are operated by a pressurised pilot medium, often air.The valve features a Pneumatic Actuators. The pilot medium flows into the actuator cylinder under pressure and causes the piston to act so that the seat seal opens or closes permitting or prohibiting flow.

Angle Valve Applications

Typical applications include:

- Air drying equipment

- Autoclaves

- Bottling equipment

- Cooling

- Dispensing equipment

- Dye mixing

- Gas

- Ink mixing

- Liquids

- Paint mixing

- Pollution management

- Pre-heating

- Process control

- Steam distribution

- Sterilisers

- Textile equipment