Difference between revisions of "Trough Conveyors"

Jump to navigation

Jump to search

| Line 7: | Line 7: | ||

* Please start editing this page after the /noinclude | * Please start editing this page after the /noinclude | ||

* -------------------------------------------------></noinclude> | * -------------------------------------------------></noinclude> | ||

[[File:Trough conveyors.jpg|thumb|right|]] | |||

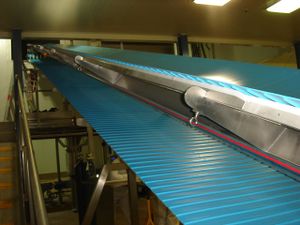

'''Trough Conveyors''' are used where the materials being conveyed need to be troughed so that they don't fall off the conveyor . These [[Conveyors ]]are ideal for any bulk handling situation. There are many applications for this type of conveyor depending on the material that needs to be conveyed. | |||

Trough Conveyors are designed to convey material at a higher speed. The rubber belt rides on angled rollers or [[Idlers]] that form a trough. They can be used for light to medium duty baler, compactor and shredder feed systems. | |||

Latest revision as of 21:59, 29 August 2012

Trough Conveyors are used where the materials being conveyed need to be troughed so that they don't fall off the conveyor . These Conveyors are ideal for any bulk handling situation. There are many applications for this type of conveyor depending on the material that needs to be conveyed.

Trough Conveyors are designed to convey material at a higher speed. The rubber belt rides on angled rollers or Idlers that form a trough. They can be used for light to medium duty baler, compactor and shredder feed systems.