Difference between revisions of "Worm Pumps"

(Created page with "Category:Pumps{{Knoppen}} <noinclude><!------------------------------------------------ * READ THIS FIRST * Only edit this page if you can improve the content. * Improper us...") |

|||

| Line 7: | Line 7: | ||

* Please start editing this page after the /noinclude | * Please start editing this page after the /noinclude | ||

* -------------------------------------------------></noinclude> | * -------------------------------------------------></noinclude> | ||

This | |||

[[File:Screw_pump1.jpg| thumb| right]] | |||

[[File:Screwpump2.jpg| thumb| right]] | |||

[[File:Screw_pump3.jpg| thumb| right]] | |||

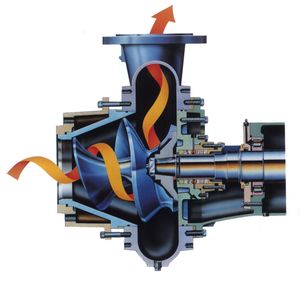

A '''Worm Pump''' (more often referred to as 'screw pump') is a positive displacement pump that use one or several screws to move fluids or solids along the screw(s) axis. In its simplest form (the Archimedes' screw pump), a single screw rotates in a cylindrical cavity, thereby moving the material along the screw's spindle. This ancient construction is still used in many low-tech applications, such as irrigation systems and in agriculturural machinery for transporting grain and other solids. | |||

Development of the screw pump has led to a variety of multi-axis technologies where carefully crafted screws rotate in opposite directions or remains stationary within a cavity. The cavity can be profiled, thereby creating cavities where the pumped material is "trapped". | |||

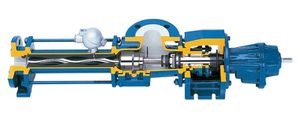

In offshore and marine installations, a three spindle screw pump is often used to pump high pressure viscous fluids. Three screws drive the pumped liquid forth in a closed chamber. As the screws rotate in opposite directions, the pumped liquid moves along the screws spindles. | |||

Three-Spindle screw pumps are used for transport of viscous fluids with lubricating properties. They are suited for a variety of applications such as fuel-injection, oil burners, boosting, hydraulics, fuel, lubrication, circulating, feed and so on. | |||

Compared to [[Centrifugal Pumps]], [[Positive Displacement Pumps]] have several advantages. The pumped fluid is moving axially without turbulence which eliminates foaming that would otherwise occur in viscous fluids. They are also able to pump fluids of higher viscosity without losing flow rate. Also, changes in the pressure difference have little impact on PD pumps compared to centrifugal pumps. | |||

Revision as of 03:14, 5 March 2012

A Worm Pump (more often referred to as 'screw pump') is a positive displacement pump that use one or several screws to move fluids or solids along the screw(s) axis. In its simplest form (the Archimedes' screw pump), a single screw rotates in a cylindrical cavity, thereby moving the material along the screw's spindle. This ancient construction is still used in many low-tech applications, such as irrigation systems and in agriculturural machinery for transporting grain and other solids.

Development of the screw pump has led to a variety of multi-axis technologies where carefully crafted screws rotate in opposite directions or remains stationary within a cavity. The cavity can be profiled, thereby creating cavities where the pumped material is "trapped".

In offshore and marine installations, a three spindle screw pump is often used to pump high pressure viscous fluids. Three screws drive the pumped liquid forth in a closed chamber. As the screws rotate in opposite directions, the pumped liquid moves along the screws spindles.

Three-Spindle screw pumps are used for transport of viscous fluids with lubricating properties. They are suited for a variety of applications such as fuel-injection, oil burners, boosting, hydraulics, fuel, lubrication, circulating, feed and so on.

Compared to Centrifugal Pumps, Positive Displacement Pumps have several advantages. The pumped fluid is moving axially without turbulence which eliminates foaming that would otherwise occur in viscous fluids. They are also able to pump fluids of higher viscosity without losing flow rate. Also, changes in the pressure difference have little impact on PD pumps compared to centrifugal pumps.