Difference between revisions of "Direct Drive Mixers"

Jump to navigation

Jump to search

PurplePen19 (talk | contribs) (→Video) |

|||

| Line 1: | Line 1: | ||

[[Category:Mixing]]{{Knoppen}} | [[Category:Mixing]]{{Knoppen}} | ||

[[File:Direct Drive Mixers1.jpg|thumb|200px|right|Direct Drive Mixers]] | [[File:Direct Drive Mixers1.jpg|thumb|200px|right|Direct Drive Mixers]] | ||

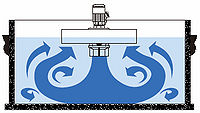

[[File:Direct Drive Mixers_2.jpg|thumb|200px|right|Direct Drive Mixers Diagram]] | [[File:Direct Drive Mixers_2.jpg|thumb|200px|right|Direct Drive Mixers Diagram]] | ||

'''Direct Drive Mixers''' are ideal for water treatment industries. This mixer uses a powerful downward propeller driven pumping action without introducing any additional oxygen into the wastewater. The mixer helps to disperse oxygen into an aeration basin, pond or lagoon. It also keeps solids in suspension for optimal biological activity. | '''Direct Drive Mixers''' are ideal for water treatment industries. This mixer uses a powerful downward propeller driven pumping action without introducing any additional oxygen into the wastewater. The mixer helps to disperse oxygen into an aeration basin, pond or lagoon. It also keeps solids in suspension for optimal biological activity. | ||

| Line 17: | Line 8: | ||

For those aeration applications where the mixing energy requirement is greater than the aeration requirement, the direct drive mixer will provide mixing more efficiently than a combined aeration/mixing device. This may result in considerable energy savings while providing greater flexibility of operation. | For those aeration applications where the mixing energy requirement is greater than the aeration requirement, the direct drive mixer will provide mixing more efficiently than a combined aeration/mixing device. This may result in considerable energy savings while providing greater flexibility of operation. | ||

Examples | |||

==Examples== | |||

*Sludge systems | |||

*Back-mixing | |||

*Biomass conditioning | |||

*Biomass suspension | |||

*Gentrification basins | |||

*Directional mixing | |||

*Equalization | |||

*Air systems | |||

*Neutralization | |||

*Storm flow basins | |||

==Features== | ==Features== | ||

Directional mixing. | *Directional mixing. | ||

Fully adjustable mounting system. | *Fully adjustable mounting system. | ||

High basin mixing efficiency. | *High basin mixing efficiency. | ||

Low initial cost, and less expensive to install and maintain | *Low initial cost, and less expensive to install and maintain | ||

Motor options: explosion proof, high efficiency | *Motor options: explosion proof, high efficiency | ||

No couplings, gear boxes or submerged bearings | *No couplings, gear boxes or submerged bearings | ||

Downflow discharge eliminates short-circuiting | *Downflow discharge eliminates short-circuiting | ||

Standard mooring arrangements | *Standard mooring arrangements | ||

Horsepower: 3 to 75 | *Horsepower: 3 to 75 | ||

==Video== | ==Video== | ||

<youtube>A7sTObBzWcw</youtube> | <youtube>A7sTObBzWcw</youtube> | ||

Latest revision as of 18:52, 3 January 2013

Direct Drive Mixers are ideal for water treatment industries. This mixer uses a powerful downward propeller driven pumping action without introducing any additional oxygen into the wastewater. The mixer helps to disperse oxygen into an aeration basin, pond or lagoon. It also keeps solids in suspension for optimal biological activity.

Applications

For those aeration applications where the mixing energy requirement is greater than the aeration requirement, the direct drive mixer will provide mixing more efficiently than a combined aeration/mixing device. This may result in considerable energy savings while providing greater flexibility of operation.

Examples

- Sludge systems

- Back-mixing

- Biomass conditioning

- Biomass suspension

- Gentrification basins

- Directional mixing

- Equalization

- Air systems

- Neutralization

- Storm flow basins

Features

- Directional mixing.

- Fully adjustable mounting system.

- High basin mixing efficiency.

- Low initial cost, and less expensive to install and maintain

- Motor options: explosion proof, high efficiency

- No couplings, gear boxes or submerged bearings

- Downflow discharge eliminates short-circuiting

- Standard mooring arrangements

- Horsepower: 3 to 75

Video