Transmissions

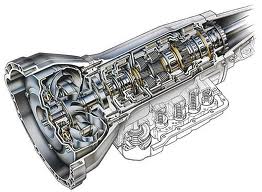

Transmission is a machine consists of a power source and a power transmission system, which provides controlled application of the power. Merriam-Webster defines transmission as an assembly of parts including the speed-changing Gears and the propeller shaft by which the power is transmitted from an engine to a live axle.Often transmission refers simply to the gearbox that uses gears and gear trains to provide speed and torque conversions from a rotating power source to another device.

In British English, the term transmission refers to the whole drive train, including clutch, gearbox, prop shaft , differential, and final drive shafts. In American English, however, the distinction is made that a gearbox is any device which converts speed and torque, whereas a transmission is a type of gearbox that can be shifted to dynamically change the speed-torque ratio such as in a vehicle.

The most common use is in motor vehicles, where the transmission adapts the output of the internal combustion engine to the drive wheels. Such engines need to operate at a relatively high rotational speed, which is inappropriate for starting, stopping, and slower travel. The transmission reduces the higher engine speed to the slower wheel speed, increasing torque in the process. Transmissions are also used on pedal bicycles, fixed machines, and anywhere else where rotational speed and torque needs to be adapted.

Often, a transmission will have multiple gear ratios or simply gears, with the ability to switch between them as speed varies. This switching may be done manually , or automatically. Directional control may also be provided. Single-ratio transmissions also exist, which simply change the speed and torque of motor output.

In motor vehicles, the transmission will generally be connected to the crankshaft of the engine. The output of the transmission is transmitted via driveshaft to one or more differentials, which in turn, drive the wheels. While a differential may also provide gear reduction, its primary purpose is to permit the wheels at either end of an axle to rotate at different speeds as it changes the direction of rotation.Conventional gear or belt transmissions are not the only mechanism for speed or torque adaptation. Alternative mechanisms include torque converters and power transformation . Hybrid configurations also exist.

Explanation

Early transmissions included the right-angle drives and other gearing in windmills, horse-powered devices, and steam engines, in support of pumping, milling, and hoisting.

Most modern Gearboxes are used to increase torque while reducing the speed of a prime mover output shaft . This means that the output shaft of a gearbox will rotate at a slower rate than the input shaft, and this reduction in speed will produce a mechanical advantage, causing an increase in torque. A gearbox can be set up to do the opposite and provide an increase in shaft speed with a reduction of torque. Some of the simplest gearboxes merely change the physical direction in which power is transmitted.

Many typical automobile transmissions include the ability to select one of several different gear ratios. In this case, most of the gear ratios are used to slow down the output speed of the engine and increase torque. However, the highest gears may be overdrive types that increase the output speed.

Uses

Gearboxes have found use in a wide variety of different often stationary applications, such as wind turbines.Transmissions are also used in agricultural, industrial, construction, mining and automotive equipment. In addition to ordinary transmission equipped with gears, such equipment makes extensive use of the hydrostatic drive and electrical adjustable-speed drives.

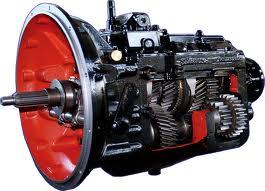

Simple

The simplest transmissions, often called gearboxes to reflect their simplicity , provide gear reduction , sometimes in conjunction with a right-angle change in direction of the shaft . These are often used on PTO-powered agricultural equipment, since the axial PTO shaft is at odds with the usual need for the driven shaft, which is either vertical, or horizontally extending from one side of the implement to another . More complex equipment, such as silage choppers and snow blowers, have drives with outputs in more than one direction.

The gearbox in a wind turbine converts the slow, high-torque rotation of the turbine into much faster rotation of the electrical generator. These are much larger and more complicated than the PTO gearboxes in farm equipment. They weigh several tons and typically contain three stages to achieve an overall gear ratio from 40:1 to over 100:1, depending on the size of the turbine. The first stage of the gearbox is usually a planetary gear, for compactness, and to distribute the enormous torque of the turbine over more teeth of the low-speed shaft.Durability of these gearboxes has been a serious problem for a long time.

Regardless of where they are used, these simple transmissions all share an important feature: the gear ratio cannot be changed during use. It is fixed at the time the transmission is constructed.For transmission types that overcome this issue, see Continuously Variable Transmission, also known as CVT.