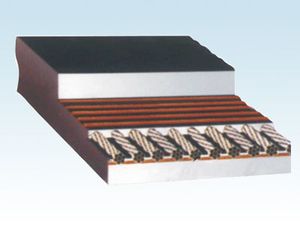

Steelcord Belts

Jump to navigation

Jump to search

Steelcord Belts are widely used in high strength, long distance and heavy load transportation of materials, and they are also used in high strength and short distance transportation of materials on special occasions.

The current mining techniques demand that Conveyor Belts handle ever greater volumes, with increased centre distances and high lifts, all of which necessitated a stronger belting. Yet, the high strength of the steel cord tension carrier is not the only reason why steel cord belts are increasingly being used as an optimum and economic alternative to other bulk material handling alternatives.

Characteristics

- High tensile strength:The belts are suitable for large span, long distance transportation Of materials

- Small elongation in use:The belts need only a very short take-up stroke distance.

- Small diameter of drive pulley:The belt body has a layer of longitudinally arranged steel cords as its skeleton, and thus is resistant to flex fatigue. Therefore, drive pulley Of smaller diameter can be used to make the equipment smaller.

- High adhesion between rubber and steel cord:The cords are coated with zinc on there surface, and also the rubber used have the property of good adhesion with steel cords. Therefore, the rubber is tightly adhered to the steel cords and is resistant to shock and difficult to drop, so the rubber belts are long in life.

- Even tension of steel cords:Out of our advanced techniques in manufacturing, the steel cords are very evenly arranged and have the same tension, so the belts are well balanced in running and difficult to run awry.

- Good trough ability:As the belt body has no transverse skeleton, it is easy to form a deep trough, so the belts can load more materials and prevent the materials from escaping.

- Inspection of the belt X-rays:Users can use X-rays to inspect damages of the skeleton steel cords on the conveyor machines to prevent accidents from happening.