Difference between revisions of "Disc Drag Conveyors"

(Created page with "Category:Conveying{{Knoppen}} <noinclude><!------------------------------------------------ * READ THIS FIRST * Only edit this page if you can improve the content. * Imprope...") |

|||

| Line 7: | Line 7: | ||

* Please start editing this page after the /noinclude | * Please start editing this page after the /noinclude | ||

* -------------------------------------------------></noinclude> | * -------------------------------------------------></noinclude> | ||

[[File:Disc-drag-conveyor.jpg|right|thumb|Disc Drag Conveyors]] | |||

'''Disc Drag Conveyor''' is designed for versatility in gentle material conveying operation. It allows the most flexible installation in any direction (vertically, horizontally and any angle in between), therefore to save space for new plant, or to fit into any existing facilities regardless of what lies between the inlet and outlet. Because of the closed design, there is no possibility of dust pollution in the working area at all. The unique design of flights and chains makes the [[Tubular Drag Conveyors]] only move the solid materials but minimize the attrition to them. Thus, very fragile solid can be delivered within the tubular drag conveyor, and for blends of different materials, there is no risk to separate them. | |||

Disc drag conveyors are used where other conventional mass conveyors will not do the job, and for heavy industrial applications where continuous service and high degree of reliability are of atmost importance. | |||

==Features== | |||

* Totally enclosed, dust-free, contamination-free | |||

* Single or complex circuit regardless of what lies between the inlet and outlet | |||

* Single driver, low energy consumption | |||

* Robust chain and sprocket driver | |||

* Able to handling hot, cold, wet, dry materials | |||

* Multiple points of feeding | |||

* Multiple points of discharging | |||

* Tube made by carbon steel, stainless steel, PVC, PP, etc | |||

* Different sizes of tube available | |||

* Cross section of round, square or other shape | |||

* Chain made by stainless steel 304 or 316 | |||

* Flight made by UHMWPE, nylon, PTFE, polyurethane,steel, etc | |||

* Variable speed control | |||

Latest revision as of 03:33, 23 August 2012

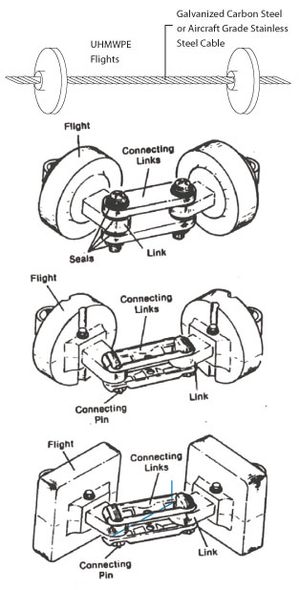

Disc Drag Conveyor is designed for versatility in gentle material conveying operation. It allows the most flexible installation in any direction (vertically, horizontally and any angle in between), therefore to save space for new plant, or to fit into any existing facilities regardless of what lies between the inlet and outlet. Because of the closed design, there is no possibility of dust pollution in the working area at all. The unique design of flights and chains makes the Tubular Drag Conveyors only move the solid materials but minimize the attrition to them. Thus, very fragile solid can be delivered within the tubular drag conveyor, and for blends of different materials, there is no risk to separate them.

Disc drag conveyors are used where other conventional mass conveyors will not do the job, and for heavy industrial applications where continuous service and high degree of reliability are of atmost importance.

Features

- Totally enclosed, dust-free, contamination-free

- Single or complex circuit regardless of what lies between the inlet and outlet

- Single driver, low energy consumption

- Robust chain and sprocket driver

- Able to handling hot, cold, wet, dry materials

- Multiple points of feeding

- Multiple points of discharging

- Tube made by carbon steel, stainless steel, PVC, PP, etc

- Different sizes of tube available

- Cross section of round, square or other shape

- Chain made by stainless steel 304 or 316

- Flight made by UHMWPE, nylon, PTFE, polyurethane,steel, etc

- Variable speed control