Difference between revisions of "Electromagnetic Separators"

m (moved Electro Magnetic Separators to Electromagnetic Separators) |

|||

| Line 7: | Line 7: | ||

* Please start editing this page after the /noinclude | * Please start editing this page after the /noinclude | ||

* -------------------------------------------------></noinclude> | * -------------------------------------------------></noinclude> | ||

This | [[File:Electro_mag_01.jpg|thumb|right|Electormagnetic Separator]] | ||

[[File:Electro_mag_02.jpg|thumb|right|Electromagnetic Suspension-Overband Separators With Self Cleaning Band]] | |||

[[File:Electro_mag_03.jpg|thumb|right|Nippon Electromagnetic separator]] | |||

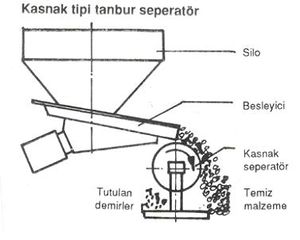

[[File:Electro_mag_04.jpg|thumb|right|Kasnak nipi tanbur separator]] | |||

Electromagnetic separators or [[magnetic separators|magnetic separators]]are designed specifically to remove fine iron powders introduced to the base material during the grinding process. This is a process in which magnetically susceptible material is extracted from a mixture using a magnetic force. This separation technique can be useful in mining iron as it is attracted to a magnet.Longi Magnet Company is a professional electromagnetic separator manufacturer and supplier. Our electromagnetic separators could be equipped with different conveyors for removing undesired iron impurities with a weight ranging from 0.1 to 35 kg from bulk non-magnetic materials. It is suitable for belts with a speed less than or equals to 4.5m/s. With this electromagnetic separator, materials are refined and iron impurities are collected. This electromagnetic separator therefore finds wide applications in power plants, mines, building material factories, and other factories in metallurgical and food industries. Our Longi electromagnetic separator is available in manual-cleaning (plate type) and self-cleaning (plate type). We feature cooling methods like air cooling, fan cooling and oil cooling. | |||

==Advantages of Electromagnetic Separator== | |||

The advantages of Electromagnetic separators are listed below- | |||

i. Fields to magnetize the collecting elements can be matched to the separation requirements, from about 1 through 20 kilogauss in the empty separating space. | |||

ii. Large volumes of magnetized matrix spaces can be generated to meet processing needs. | |||

iii. Separating spaces can be filled with a virtually endless variety of matrix elements. | |||

iv. The magnetic field can be conveniently turned off to allow easy cleaning of the matrix, making it possible to automate the cleaning cycle. | |||

v. Equipment can be designed to meet unusual processing conditions including high temperature, high pressure and many corrosive products. | |||

vi. Equipment is available for use in hazardous environments. | |||

==Working Principle== | |||

The working principle of magnetic separator is that when the slurry into the magnetic field, one of the strong magnetic minerals are adsorbed on the cylinder surface, if the magnetic and non-magnetic minerals is to get rid of discharge, while the adsorption on the surface of the cylinder with the cylinder rotating strong magnetic minerals, was brought the magnetic field, with the rinse water into the concentrate tank to complete the sorting operation. | |||

==Features of Electromagnetic separator== | |||

Features | |||

i. The coil of our electromagnetic separator is specially processed with good oxidation and rust resistance, thus ensuring the heat transferring capacity and insulation performance of the coil. | |||

ii. It is of big magnetic penetration depth and strong suction force. | |||

iii. It is of low energy consumption and stable performance. | |||

iv. With compact structure, this electromagnetic separator is easy to install and maintain. | |||

v. Good heat diffusion and stable temperature rise. | |||

vi. This magnetic separator can suck or throw iron materials continuously. | |||

vii. The belt is provided with automatic rectifying function. | |||

==Related Types== | |||

*[[Magnetic Separator]] | |||

==Related Youtube Video== | |||

<youtube>N5yFF0AU-So</youtube> | |||

Revision as of 14:59, 12 September 2012

Electromagnetic separators or magnetic separatorsare designed specifically to remove fine iron powders introduced to the base material during the grinding process. This is a process in which magnetically susceptible material is extracted from a mixture using a magnetic force. This separation technique can be useful in mining iron as it is attracted to a magnet.Longi Magnet Company is a professional electromagnetic separator manufacturer and supplier. Our electromagnetic separators could be equipped with different conveyors for removing undesired iron impurities with a weight ranging from 0.1 to 35 kg from bulk non-magnetic materials. It is suitable for belts with a speed less than or equals to 4.5m/s. With this electromagnetic separator, materials are refined and iron impurities are collected. This electromagnetic separator therefore finds wide applications in power plants, mines, building material factories, and other factories in metallurgical and food industries. Our Longi electromagnetic separator is available in manual-cleaning (plate type) and self-cleaning (plate type). We feature cooling methods like air cooling, fan cooling and oil cooling.

Advantages of Electromagnetic Separator

The advantages of Electromagnetic separators are listed below-

i. Fields to magnetize the collecting elements can be matched to the separation requirements, from about 1 through 20 kilogauss in the empty separating space.

ii. Large volumes of magnetized matrix spaces can be generated to meet processing needs.

iii. Separating spaces can be filled with a virtually endless variety of matrix elements.

iv. The magnetic field can be conveniently turned off to allow easy cleaning of the matrix, making it possible to automate the cleaning cycle.

v. Equipment can be designed to meet unusual processing conditions including high temperature, high pressure and many corrosive products.

vi. Equipment is available for use in hazardous environments.

Working Principle

The working principle of magnetic separator is that when the slurry into the magnetic field, one of the strong magnetic minerals are adsorbed on the cylinder surface, if the magnetic and non-magnetic minerals is to get rid of discharge, while the adsorption on the surface of the cylinder with the cylinder rotating strong magnetic minerals, was brought the magnetic field, with the rinse water into the concentrate tank to complete the sorting operation.

Features of Electromagnetic separator

Features

i. The coil of our electromagnetic separator is specially processed with good oxidation and rust resistance, thus ensuring the heat transferring capacity and insulation performance of the coil.

ii. It is of big magnetic penetration depth and strong suction force.

iii. It is of low energy consumption and stable performance.

iv. With compact structure, this electromagnetic separator is easy to install and maintain.

v. Good heat diffusion and stable temperature rise.

vi. This magnetic separator can suck or throw iron materials continuously.

vii. The belt is provided with automatic rectifying function.

Related Types

Related Youtube Video