Difference between revisions of "Steel Pallets"

(Created page with "Category:Pallets{{Knoppen}} <noinclude><!------------------------------------------------ * READ THIS FIRST * Only edit this page if you can improve the content. * Improper ...") |

|||

| (One intermediate revision by the same user not shown) | |||

| Line 6: | Line 6: | ||

* Please do not edit the sponsored link on the top right corner. | * Please do not edit the sponsored link on the top right corner. | ||

* Please start editing this page after the /noinclude | * Please start editing this page after the /noinclude | ||

* -------------------------------------------------></noinclude> | * | ||

-------------------------------------------------></noinclude> | |||

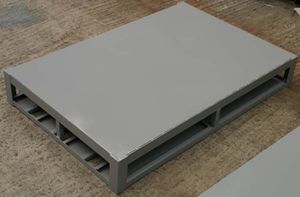

[[File:STEEL PALLET.jpg|thumb|right|Steel Pallet]] | |||

[[File:STEEL PALLETS 2.gif|thumb|right|Steel Pallet]] | |||

'''Steel Pallets''' are strong and are used for heavy loads, high-stacking loads, long term dry storage, and loads moved by abusive logistic systems. They are often used for military ammunition | |||

Metal [[Pallets]] make up less than 1% of the market. Materials include carbon steel, stainless steel, and aluminum. Of these, carbon steel offers excellent durability at the lowest cost. Stainless steel doesn’t require a paint coating, and is preferred for such applications as clean room environments. Aluminum offers the durability of steel at a lighter weight. Carbon steel units are expensive compared to wood, and stainless and aluminum cost about 2-3 times that of carbon steel. Long term costs, however, can be lower than wood. General advantages of metal pallets are high strength and stiffness, excellent durability, bug free, no splinters, sanitary, and recyclable. Disadvantages include a higher initial price, significant weight, low friction, and susceptibility to rusting. Metal is primarily used in captive or closed loop environments where durability and product protection are key performance requirements. Metal units today are increasingly price competitive and lighter in weight. Primary industries that use metal pallets include automotive, pharmaceutical, lawn tractors, motorcycles, and tires. | |||

Latest revision as of 01:21, 3 August 2012

Steel Pallets are strong and are used for heavy loads, high-stacking loads, long term dry storage, and loads moved by abusive logistic systems. They are often used for military ammunition

Metal Pallets make up less than 1% of the market. Materials include carbon steel, stainless steel, and aluminum. Of these, carbon steel offers excellent durability at the lowest cost. Stainless steel doesn’t require a paint coating, and is preferred for such applications as clean room environments. Aluminum offers the durability of steel at a lighter weight. Carbon steel units are expensive compared to wood, and stainless and aluminum cost about 2-3 times that of carbon steel. Long term costs, however, can be lower than wood. General advantages of metal pallets are high strength and stiffness, excellent durability, bug free, no splinters, sanitary, and recyclable. Disadvantages include a higher initial price, significant weight, low friction, and susceptibility to rusting. Metal is primarily used in captive or closed loop environments where durability and product protection are key performance requirements. Metal units today are increasingly price competitive and lighter in weight. Primary industries that use metal pallets include automotive, pharmaceutical, lawn tractors, motorcycles, and tires.