Backwash Filters

Most drinking water systems use filters to collect, catch, or gather particles from an incoming flow. When the filter’s pores become clogged, they need to be cleaned. One of the best ways to clean a drinking water system’s filter is to backwash filtering it, meaning reversing the flow and increasing the velocity at which water passes back through the filter. This, in effect, blasts the clogged particles off of the filter.

Although every filter is unique, the principles of backwashing are similar for all of them. One key ingredient to a good filter backwash is using clean water, usually out of the clear well, first storage tank, or distribution system. This Tech Brief examines the most common filters: conventional and direct filtration. These filters use either pressure or rapid rate gravity processes.

When to backwash?

The cleanliness or cloudiness (turbidity) of the water coming out of the filter just before it goes into the clear well is the best way to determine when to backwash. A good rule of thumb is 0.1 nephelometric turbidity units (NTU) on each individual filter’s effluent. This may sound a little extreme when the combined filter effluent (CFE) for conventional and direct filtration systems is 0.3 NTU. But 0.1 NTU gives the operator time to react to any problems within the treatment system. Head loss on the filter also indicates the need to backwash. Head loss is usually measured with a negative pressure gauge. As the filter gets clogged, more negative pressure is created. The pressure usually starts near zero pounds per square inch (psi) or approximately one foot of head loss on the clean filter. Then the pressure will increase in a linear fashion in the negative direction to approximately -2.5 to -4 psi on rapid-rate, gravity filters and some pressure filters or about six to 10 feet of head loss. The more clogged the filter, the greater the head loss. This calculation may be different depending on the filter type and make. Some small plants will just have a clear tube with water indicating pressure differences. The water level in the tube rises as the pressure difference increases. For every one psi measure, there is about 2.31 feet in a column of water. For every one foot in a column of water, there is 0.434 psi of pressure difference. The clear tube can be marked with the pressure difference in negative psi, or it could have a single mark, indicating it is time to backwash. A couple of other indicators really only work when a water system has consistent raw water turbidity. These indicators are gallons filtered or run time. When the raw water is consistent, operators usally can tell when to backwash based on the pump’s run time.

How long to backwash?

Backwash until the water runs clear (provided there is enough clean water to do unlimited backwashing). Most systems don’t have unlimited amounts of clean water, which is why it is important not to get the filter too dirty or overextend the filter run time. Some small systems don’t want to use a lot of water while backwashing because they may have limited water set aside in the clear well, or the system could be dealing with drought and must conserve as much water as possible. However, systems should not think of it as wasting water because the filters must be clean to ensure good water quality for their customers. There are several techniques that can be used to enhance or speed up the backwashing process:

- Add a surface wash system. This system is a series of water jets that can be fixed or a revolving apparatus and comes on at the beginning of the backwash cycle and usually ends before the middle of the cycle. There also can be another series of water jets in the media bed itself (subsurface wash) that come on when the filter bed is fully fluidized (full backwash). For a surface wash to work adequately, at least 45 psi is needed as well as a properly installed vacuum breaker. The flow for fixed nozzles should be two gallons per minute per square foot and 0.5 gallons per minute per square foot for rotating system.

- Add an air scour system. This system is a series of small air pipes with diffusers in the under-drain or above the under-drains that blow uncontaminated air to help break-up mud balls. (The process is similar to when kids blow in the straw in their drinks.).

- Always spray the side of the filter walls down with clean water using a potable water hose during the backwash on a rapid-rate gravity filter.

- Increase or vary the backwash rate, but not too much since the support gravel could become displaced and creating a big problem.

After Backwash

Several techniques can be employed to avoid the dreaded turbidity spike, which is the first slug of water that comes through the filter after the backwash cycle once the filter is operational again. This turbidity spike can occur anywhere from a few minutes to 40 or more minutes after returning to filter operation mode. The turbidity can vary from a negligible NTU to as high as 1.5 NTU or more. If the turbidity on the individual filter gets any higher, there may be problems with the filter or the filter backwash. One easy way to avoid the turbidity spike is to let the filter “ripen.” Ripening the filter means that the operator allows the filter to sit for a while after the backwash cycle. Some small plants can even perform the backwash at the end of the day, before the filter is shut down and allow the filter to sit overnight. Filter ripening takes from 30 minutes to 24 hours. In most cases, however, the longer the filter sits, the better. Filter ripening doesn’t cost anything and requires no special piping, but many systems don’t have the luxury of this time.

Related Topics

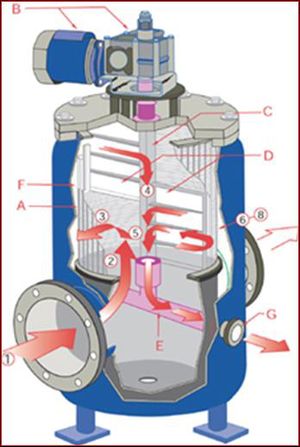

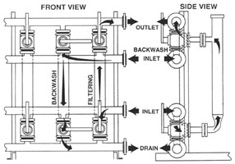

- Automatic Backwash Filter

Video